Self Clinching Studs

Self-Clinching fasteners provide strong load bearing male or female threads in thin steel and aluminium panels.

Installation is neat and easy.

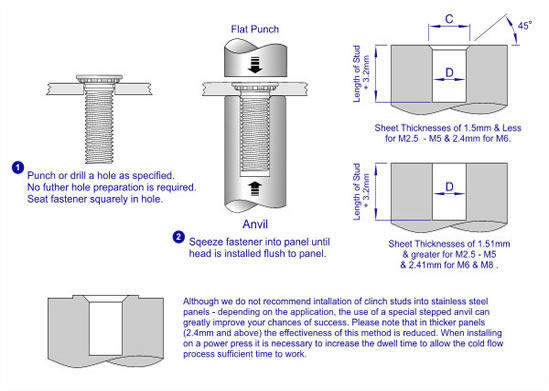

Simply locate the fastener into a pre-prepared hole and apply a parallel squeezing force to embed the fastener into the panel.

Self-Clinching fasteners work by utilizing a special clinch feature.

When the part is pressed into the hole, the parent material cold-flows into the clinch feature, effectively locking the fastener into the panel, providing excellent torque-out and push-out performance.

Self-Clinching fasteners require a parallel squeezing force to be applied for correct installation.

Equally important is the length of time the force is applied. Sufficient time must be allowed for the cold-flow clinching process to work (this is often referred to as the dwell time when installing on a hydraulic press).

Self Clinching Studs

A self clinching stud is designed to become a permanent fixture of the part, component, or device onto which it’s installed. Installation is usually performed during the initial fabrication stage or in final assembly of the metal chassis. Parallel squeezing force is applied in order to secure the stud to the sheet metal panel.

For the best dimensional accuracy and performance, it is recommended that all holes in the sheet metal application be punched.

These externally threaded fasteners become permanently mounted to a metal framework, reducing costs and assembly time by eliminating the necessity for loose hardware and additional installation processes.

Self clinching studs are used for varying purposes, though all varieties are built to withstand high levels of torque, heavy weights, and constant, repeated pull by the attached components.

Available in the following material options

Clinch Stud FH Mild Steel Zinc Plated A2E15: Download Product Datasheet

Clinch Stud FHS Stainless Steel AISI 304 B4E15: Download Product Datasheet

Clinch Stud FH4 Stainless Steel Special B7E15: Download Product Datasheet

Clinch Stud Heavy HFHS Stainless Steel AISI 304 B4E14: Download Product Datasheet

Clinch Stud Heavy HFH Mild Steel Zinc Plated A2E14: Download Product Datasheet

Also available in Unified Series

Clinch Stud FH Mild Steel Zinc Plated UNC/UNF A2uE15: Download Product Datasheet

Clinch Stud FHS Stainless Steel AISI 304 UNC/UNF B4uE15: Download Product Datasheet

Concealed Head Self Clinching Studs

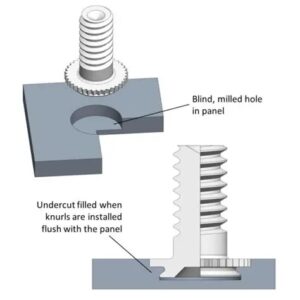

These specially designed studs provide a smooth design leaving a totally unblemished exterior of the enclosure.

The Concealed Head Studs are installed into a blind milled hole using a hollow punch and solid anvil they provide a cosmetically appealing mount that is totally undetectable on the outside of the unit.

Often used in applications such as gaming equipment and other applications where the cosmetic appearance of the unit is extremely important. When installing the mating fastener no tool is required to prevent the self clinching stud from rotating in the panel, since the fastener has become an integral part of the assembly. The fasteners provide a low cost of installation and are easily installed using a press that supplies the squeezing force required to properly seat the fastener.

Advantages:

- Installs permanently in steel or aluminum sheets as thin as 1.6 mm to provide strong and

reusable threads for mating hardware in a wide range of assembly applications. - Allows the side of the sheet opposite installation to remain smooth and unmarred.

- One side installation additionally serves to satisfy strict ingress protection (IP) requirements where the sheet must remain completely sealed from air, liquid, dust, gases or other potentially infiltrating elements.

Concealed Head Clinch Stud CHC Stainless Steel AISI 304 B4E18: Download Product Datasheet

Installation

Installation only requires a blind milled hole to the recommended size using a hollow punch and solid anvil.

Do not remove any extra material or chamfer the hole as this could result in improper installation or reduced performance.

First mill a blind hole in the panel to the correct diameter and depth. Place the fastener in to the anvil, then locate the hole over the shank of the fastener. With the panel held level, apply a parallel squeezing force until the knurled collar is installed flush to the panel surface. Do not over squeeze the fastener into the panel as this will result in panel deformation.

SPECIAL NOTE FOR INSTALLING INTO STAINLESS STEEL SHEETS

One of the very basics of self-clinching is that the fastener must be harder than the host sheet. Only then will the fastener

perform as intended.

This is particularly challenging when installing fasteners into stainless steel sheet metal.

If your application requires that the fastener clinches into stainless steel, be sure you use the fasteners specifically

designed for this purpose.