What is Thread Engagement? Thread engagement has two factors, length of thread engagement and percentage of thread engagement. Length of thread engagement is measured by the length of interaction between the fastener and mating material. Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height … Read More “Screw Thread Engagement” »

Category: Technical

With mankind reaching out to the stars, it has become important for the designers to consider suitability for extreme conditions for products. Therefore it is necessary to know what types or fastener materials are suitable for extreme conditions. Cryogenic temperatures as low as -70°C exist already on Earth with the coldest recorded temperature being -89.2°C. … Read More “Fasteners for Cryogenic Applications” »

It is common belief that a simple test for stainless steel is to check with a magnet. If it attracts, the product is not stainless steel. However, this assumption is incorrect. “The stainless steel fasteners I received stick to a magnet.” This is one of the more frequently heard complaints among users. Stainless steel fasteners … Read More “Are Stainless Steel Fasteners Magnetic?” »

What should be the minimum threads protruding beyond the nut in fastener assemblies? Possibly not much attention is given to this aspect. However it is pertinent to note that planning the correct bolt/screw length provides for a joint that ensures safety and saves space, weight and cost. A typical bolted fastener assembly will have the … Read More “Thread Protrusion of a bolted assembly” »

The need to safeguard against theft and vandalism in now becoming an essential part of design specifications. Increasingly in this competitive world, public and private property has become highly vulnerable to tampering, vandalism and theft. This creates a number of undesirable consequences. Impact of Theft and Tampering. Pilferage of Goods Vandalism – Destruction of valuable … Read More “Security Fastenings – Design Considerations” »

Anchor bolts are used extensively in concrete, brick and block masonry and cavities to make structural attachments and connections. To date, a limited amount of information has been available to aid designers and users in the selection and design of anchor bolts in various types of substrates. In new masonry construction, anchor bolts were commonly … Read More “How to select a suitable anchor fixing” »

A high performance steel wire rope always comes along with the functionally required and suitable rope end termination. The rope clip, sometimes called a u-bolt clamp or u-bolt clip is used to clamp the loose end of a length of wire rope, once it has been looped back to form an eye. These fittings consist … Read More “Safely terminate Wire Rope ends” »

Thread galling is a common, yet seldom understood problem with threaded fasteners. Galling, often referred to as a cold-welding process, can occur when the surfaces of male and female threads are placed under heavy pressure. The frustrating aspect of fastener galling is that galled nuts and bolts may pass all required inspections (threads, material, mechanical, … Read More “GALLING – The bane of fastener failure” »

COMPARATIVE ANALYSIS OF STAINLESS AND COATED CARBON STEEL FASTENERS Corrosion of stainless and carbon steel are very different, and this guidance provides information regarding general attack or surface corrosion as this is often a primary consideration when selecting fastener material. Carbon and stainless steel are the most common materials from which fasteners are manufactured and … Read More “Corrosion Analysis of Stainless and Plated Fasteners” »

AUSTENITIC STAINLESS STEEL SPRING PINS FOR DYNAMIC LOADING Austenitic nickel stainless steel Spring Pins are typically manufactured from grade SAE 301(1.4310). Austenitic stainless steel is most frequently selected for its inherent corrosion resistance. While this material possesses the spring characteristics required for proper function of a Spring Pin, it does work harden if subjected to … Read More “DYNAMIC LOADING ON SPRING PINS” »

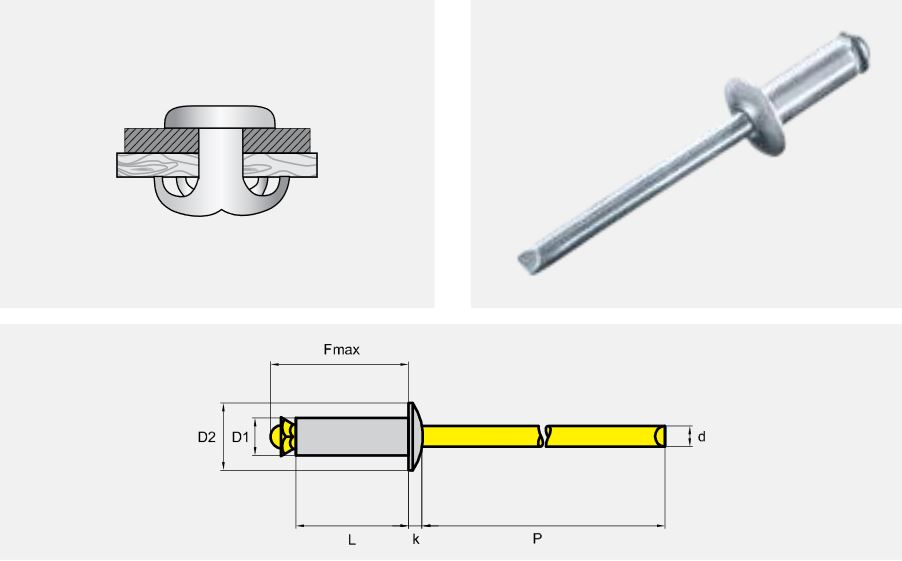

As products are increasingly utilising multi material assemblies, it has become important to understand the various options and processes available for joining the same. A common and useful method is using blind rivets which allow fast and convenient assembly. However, when joining soft or low density materials like plastics, wood, fabric etc., the rivet head … Read More “Riveting Soft Materials” »

If you thought corrosion was merely about unsightly patches of red oxide – rust – which plague steel and iron products in coastal areas and offshore applications, think again. Corrosion is present everywhere and can occur in even the most arid land-locked countries. It’s also a case of prevention being better than cure as corrosion … Read More “Corrosion Failure of Fasteners” »

Selection of the correct Fastener is very important. Begin by assessing the load that will be placed on it. Any metal fastener will hold well against a sideways (shear) force. But with a tensile force pulling the fastener straight out, holding strength becomes increasingly dependent on the threads (or formed head in the case of … Read More “Select the right Fastener” »

Never risk structures to sub-standard fixings. What is a Safety-critical application? European Technical guidelines defines as “Applications in which the failure of an anchor could result in collapse or partial collapse of a structure, cause risk to human life, or lead to a significant economic loss”. Given the importance of the reliability and stability of … Read More “Structural Safety in Anchoring” »