Blind Rivets or Pop Rivets

Blind rivets offer a number of advantages over threaded bolts. They won’t loosen when subjected to vibration and can secure joints with short clamp length.

They are the fastest way to join materials. They can be set at 150pcs to 500pcs per hour, and each setting is identical; this cuts assembly time and costs.

They are the fastest way to join materials. They can be set at 150pcs to 500pcs per hour, and each setting is identical; this cuts assembly time and costs.

Unlike threaded fasteners, there are no concerns over tool clearance, rotation failures, and secondary parts such as bolts and tapping plates, all of which add assembly time, weight, and cost.

Blind rivets are now used to assemble everything from small electronic components in cell phones to steel beams in the world’s largest bridges. They join different materials of varying thickness and can handle the most demanding environments. High-tech quality control delivers foolproof installation that lets only the correct rivets be installed the proper way in the accurate sized holes.

BLIND RIVETS TECHNICAL GUIDE

Additional benefits:

- Improved Product Design: As the rivets are installed from one side only, the need for access to both sides of work is eliminated. No more required space for tooling clearance, holding tools, and other “back side” fixture.

- Improved Design Strength: The use of only a single, drilled or punched hole, filled effectively by an expandable, high shear strength rivet, offers a great increase in part design strength over screw/bolt with nut designs.

- Quicker Assembly: Blind riveting is faster than any other joining method. Automatic feeding can deliver and set as many as 50 rivets per minute. Automatic, multiple set systems are used in some areas to set as many as 20 rivets at a time.

- Low-Cost, Lightweight, Easily Portable Tools – Manual or power tools are easy to take to the work place, reduce operator fatigue, and minimize capital expenditure.

- Strong, Reliable Fastenings, Independent of Operator Skills – Blind rivets don’t torque out like threaded fasteners, wasting time and material. Correct setting pressure is predetermined by the breaking point designed into the mandrel. So you get uniformly strong, reliable fastenings the first time – all the time.

- Vibration-Proof Assembly – Blind rivets won’t back out or vibrate loose and fall out like threaded fasteners. You eliminate costly recalls due to faulty fastenings.

- No Surface Marring – Setting tool won’t slip and mar polished or finely finished surfaces. No dents, dimpling, or wrench marks.

- Versatility – Blind rivets hold securely in thin or thick, soft or hard materials, ideal for dissimilar materials, first choice for plastics and other easily damaged components.

- High Grip Range and Joining Strengths – A blind rivet draws parts together, even when a gap exists between parts.

- Tamper-Proof – Ideal for public transportation and other public facilities where tampering and vandalism are problems. Excellent for fastening limited-access panels; authorized personnel with correct equipment easily drill out blind rivets and replace in seconds.

Blind Rivet Terms

Rivet head Diameter

The rivet flange diameter is stated at minimum and maximum dimensions.

Nominal Mandrel Diameter

The nominal (or maximum value for grooved mandrels) is shown to assist in the selection of the correct rivet tool

nosepiece.

Rivet Body Length

The nominal rivet body length is stated.

A tolerance of +/- 0.5mm should be allowed for.

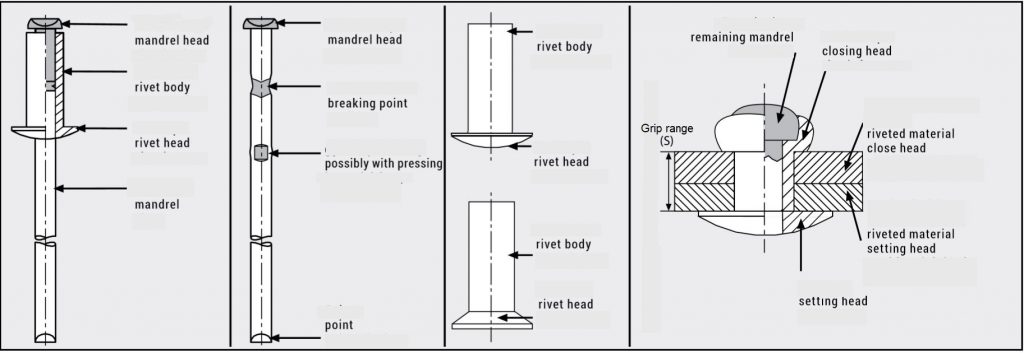

Grip Range S (Min-Max)

Grip is the combined thickness of the two materials being riveted together. Grip Range is the recommended thickness range over which the body length will consistently provide a good setting in a

hole of the specified diameter.

Hole Size

This is the recommended diameter range of the drilled/punched hole which should be burr free.

GOEBEL BLIND RIVETS

To join two pieces of material, the body of the rivet is inserted into a pre-drilled hole, then a nail rivet tool is used to pull the top of the mandrel to expand the body, clamping the two materials together. The force of the rivet tool then pops off the mandrel, leaving behind the domed head blind rivet.

Standard blind rivets can be placed on components that are accessible on one side or on two sides.

Applications: Containers/tanks, hollow body, tubes, profiles, air ducts and many others.

Characteristics: Economical • Versatile • Strong • Secure

Rivet Body

Aluminium Rivets – Lightweight with good corrosion resistance.

Steel Rivets – Stronger than Aluminium with a “flash” coating of Zinc. Low corrosion resistance.

Stainless Steel Rivets A2 – Good Strength and excellent corrosion resistance.

Stainless Steel A4 Rivets – Good Strength and increased corrosion resistance

Copper Rivets – Relatively soft. Excellent corrosion resistance and conductivity.

Monel Rivets – The strongest blind rivet material with excellent corrosion resistance and conductivity. Also excellent high temperature suitability.

Material Usage Guide

Galvanic Corrosion • When dissimilar metals come into contact in the presence of an electrolyte, a galvanic action occurs which corrodes one metal at a faster rate and the other more slowly. This phenomenon can cause major riveted joint failures and care must be taken to avoid the occurrence. The following table is a guide.

| METAL JOINED | |||||

| RIVET MATERIAL↓ | Aluminium | Coated Steel | Stainless Steel | Copper | Brass |

| Aluminium Rivets | YES | CARE | NO | NO | NO |

| Coated Steel Rivets | NO | YES | NO | NO | NO |

| Stainless Steel Rivets | CARE | CARE | YES | YES | YES |

| Copper Rivets | NO | NO | YES | YES | YES |

| Monel Rivets | NO | NO | YES | YES | YES |

| YES | Compatible | ||||

| NO | Incompatible – Avoid contact with each other | ||||

| CARE | Use with care. Painting metals will help | ||||

Hence,

1) Select materials that are as close together as possible in the Galvanic Series Chart

2) Provide a barrier between the two metals, such as paint, non-metallic washer or gaskets

3) Design the fastener as the cathode so the cathodic area is small as compared to the anodic area

4) Use a metallic finish on the fastener that is close on the chart to the mating material

Types of Blind Rivets

Standard Rivets

Go to the Standard Blind Rivets page

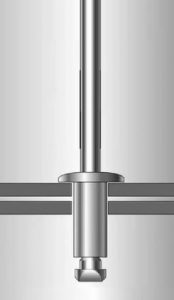

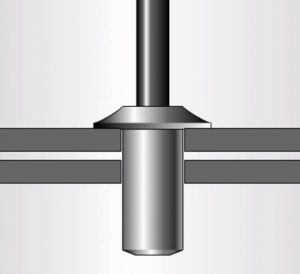

Open End Blind Rivets

General purpose rivet available in a wide range of materials and head styles.

Suitable for applications with normal load bearing requirements.

By far the most commonly used style of blind rivet due to the ease of use and low initial cost.

Easy to install with easily available hand held riveting tools.

Head Styles

Go to the Dome Head Blind rivets page

Go to the Large Flange Blind Rivets page

Go to the CSK Blind Rivets page

CLOSED End “CUP” Blind Rivets

Also known as Sealed Blind Rivet.

Designed with a completely closed body, this rivet is ideal for applications that need to be

water/pressure tight or where mandrel retention is paramount.

Used for providing a leak-proof joint.

Available in various Head and Material options.

Go to the Closed End Blind Rivets page

MULTI-GRIP Blind Rivets

For efficient joining of different grip ranges.

Multi-Grip rivets do the job of several sizes of standard rivets.

Multi-Grip rivets are best suited for applications where different material thicknesses normally require several rivet sizes.

The extensive grip range capability permits design flexibility and reduced rivet inventory, which can result in substantial cost savings.

Go to the Multi Grip Blind Rivets page

Structural Blind Rivets

Go to the Structural Blind Rivets page

Structural Blind Rivets are designed to fix elements where a high resistance to both tensile and shear strengths are required.

The High Strength Blind Rivet is versatile and especially designed for safety. It not only provides secure hold, but also takes on a load-bearing function.

High Strength Blind Rivets

For strong and reliable joints.

GO-BULB Blind Rivets

Semi-Structural Blind Rivet

Characteristics

• evenly formed closing head and a large bearing area provide high strength

• good pressure on the face of riveting holes, even with noncircular ones

• grooved mandrel offers more grip for the clamping jaws

• extremely suitable for thin sheet material

• the remainder of the mandrel is held captive in the shaft

• remaining mandrel increases shear and tensile strength

• highly resistant against vibrations

• with a fitting drill hole the connection is splash-proof

Go to the Go Bulb Structural Blind rivets page

GO-LOCK Blind Rivets

To ensure safety for structural loads, the GO-LOCK is specially designed.

Characteristics

• the mandrel head is held captive within rivet body (mechanical mandrel locking)

• watertight with suitable drill hole preparation

• high clamping capacity

• high shearing and tensile forces

• for high loads

• high resistance to vibration

Go to the Go Lock Structural Blind rivets page

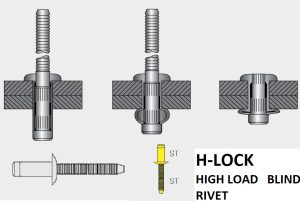

H-LOCK Structural Rivet

H-Lock Structural Rivets expand under the closing head during setting, creating an extremely powerful grip.

The grooved mandrel ensures safe locking between the elements without making the clapping sound.

With a properly prepared drill hole, this rivet is also splash-proof.

Go to the H-Lock Structural Blind rivets page

Speciality Blind Rivets

Go to the Speciality Blind Rivets page

GO PEEL Blind Rivets

Peeled rivets are extremely versatile and necessary for joining softer materials without fracturing or distortions.

These are particularly suitable for uneven surfaces or where oversized holes remain after repairs.

RILLI Grooved Blind Rivets

Tre-Go Blind Rivets

For a watertight joint. Especially suitable for roofing sheets.

For a watertight joint. Especially suitable for roofing sheets.

Triple-Claw Blind Rivets – TRI-CLAW

The problem solution for soft materials

The problem solution for soft materials

MASS Ground Connector Blind Rivets

A specialty rivet to provide a grounded connection

HAMMER DRIVE Blind Rivets

Go to the Specialty Blind Rivets page

LOCKBOLT (Pin and Collar)

LOCKBOLT is a very strong connector, it is used for construction, assembly of structures, railways, commercial vehicles, elevator equipment, which is accessible from both sides and requires high shear and tear strength

BLIND RIVET SELECTION

When selecting a blind rivet for a particular application, the following physical characteristics must be determined: style,

nature of materials, holes, thickness, joints, corrosion resistance, tensile strength, and shear strength.

Style of the Primary Head

The rivet head style determines the look of the installed rivet as it faces the viewer. In applications where the head of the rivet will be visible (such as in aircraft), consistency in appearance is important.

Use a dome rivet for general applications.

Use a flush rivet (countersunk rivet) for low clearance applications.

Use a large bearing head (large flange) rivet for covering larger holes or slots—this can be used to provide additional bearing support for joints made either of thin sheet metal or soft, brittle material, such as composites or plastic.

Nature of the Materials to Be Fastened

The rivet body material should be the same or similar to the material(s) of the two components to be joined, in order to

prevent failure or corrosion. Blind rivets are made from a variety of materials including an assortment of alloys, nylon,

and thermoplastic. The rivet body material and mandrel material may be the same or different. Various versions of rivets include those with painted, metal-plated, and protective surface finishes.

Hole Size

The size of the hole determines rivet diameter, which must be neither too small, making it harder to place the rivet,

or too large, leaving a gap that could increase shear stress on the rivet or cause installation problems. A hole that

is too large might also allow the blind head to expand in the space between the two workpieces.

Another consideration is whether the holes will be pre-drilled separately, making it more difficult to

match up the hole size and spacing in the two parts of the joint.

Material Thickness

The grip range of a joint is the thickness of the two parts combined. Rivets are available in varying grip ranges, with longer

range required for joining thicker materials.

Liquid and/or Gas Joint

Some applications require a joint to be watertight or non-permeable for gases up to a certain pressure. Examples include

pipes, appliances, and refrigerated trailers. Closed end rivets are suitable for such applications.

Corrosion Resistance

Applications subject to water, salt spray, or corrosive cleaning chemicals may require a rivet material that won’t corrode in the presence of the joint material(s). To prevent galvanic corrosion between two dissimilar metals, choose less corrosive

combinations or add a protective barrier or finish.

Strength—Shear/Tensile

Tensile strength applies to the maximum tension that the rivet can withstand along its length. Shear strength is the maximum force the rivet can withstand as the two parts of the joint tend to slide apart.

Heavy duty applications, such as agricultural equipment, require much greater shear and tensile strength. Structural rivets are considered for such applications.